Services

Wall thickness measurement

In order to be able to assess the necessity of a kettle change, we carry out wall thickness measurements for you. Using modern ultrasonic measuring technology, these measurements are carried out during operation so that no downtimes occur. The special feature of this procedure is the temperature resistance of the probe as well as the measuring electronics with various filter and memory functions. In this way, subsequent processing and analysis of the measured data is made possible.

Kettle change

In every galvanising plant, the galvanising kettle is changed at regular intervals. For this purpose it is necessary to pump the liquid zinc. Often the intermediate storage of the liquid zinc is done with holding tanks. We have specialised in these requirements.

We offer all services around the change of galvanising kettle

With various zinc pumps of different capacities, we also have the right pump for your galvanising plant. Furthermore, with our 5 holding tanks we offer you a capacity of up to 450t for the intermediate storage of liquid zinc. The heating of these apparatuses is carried out with electrical resistance heating elements.

As part of the replacement of a galvanising tank, repair work is usually carried out on the galvanising furnace. Due to our experience in this field, we are also happy to take on these tasks for you:

- Repairs to the foundation, insulation and steel construction

- Modifications and adjustments to the burner system

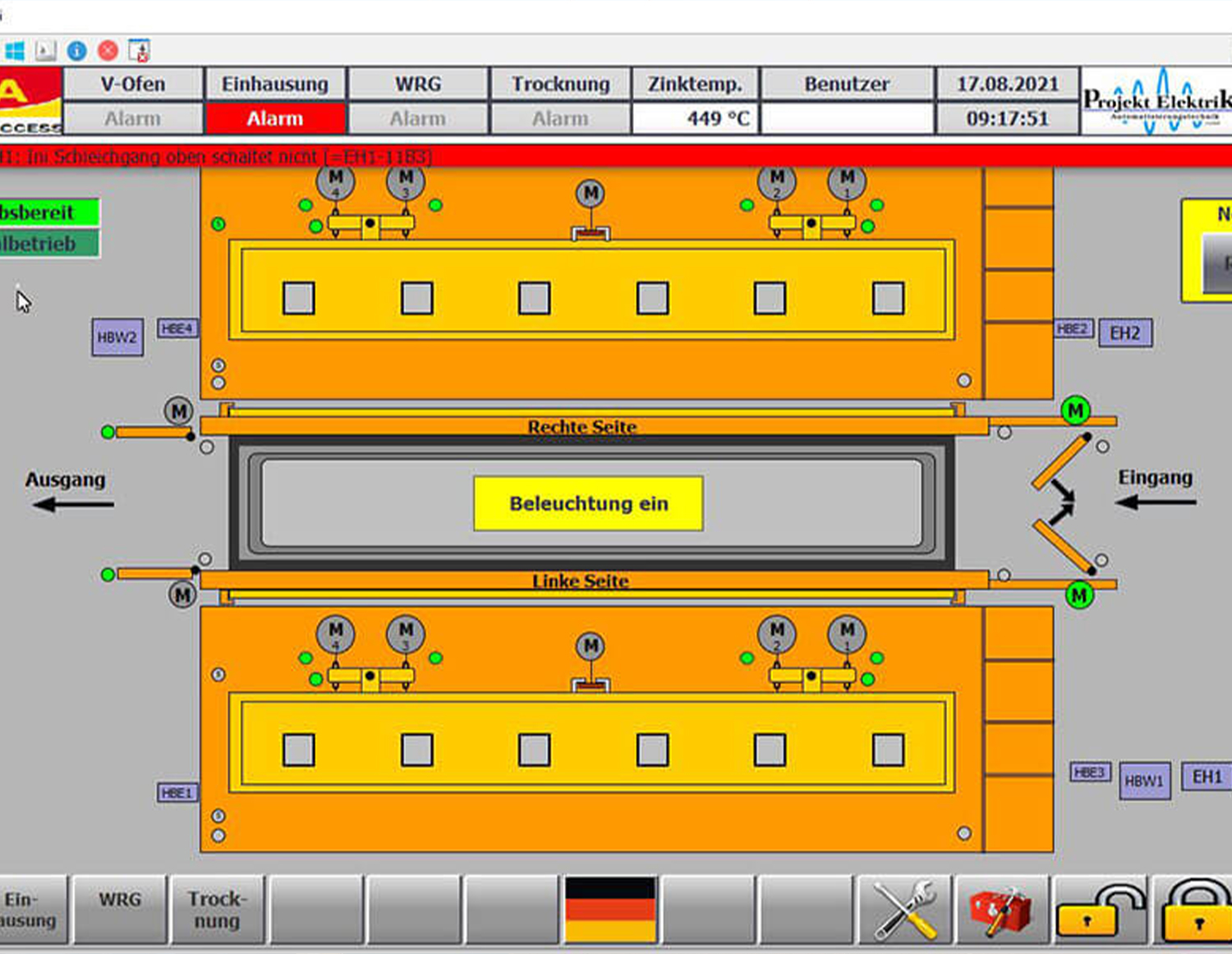

- Modernisation of the existing control technology

- Monitoring and support of the heating phase

Conclusion of maintenance contracts

To ensure that your heating technology continues to function properly in the future, you can conclude maintenance contracts with us to regularly check the condition of your system. The maintenance contracts include, among other things:

- Cleaning and adjustment of the burner system

- Checking all pipes for leaks

- Checking the fans

- Exhaust gas analysis

- Temperature adjustment between zinc bath and control system

- Checking the furnace chamber pressure control

- Inspection of all safety equipment

- Wall thickness measurement

24 hours service

In case of emergency, we are also available for you outside our business hours.